High Precision Mouldings Moulds Making Maker Plastic Injection Mold Plastic Silicone Injection Moulding Part Maker Manufacturer Product Display Product Paramenter Company Name Guangdong Engine

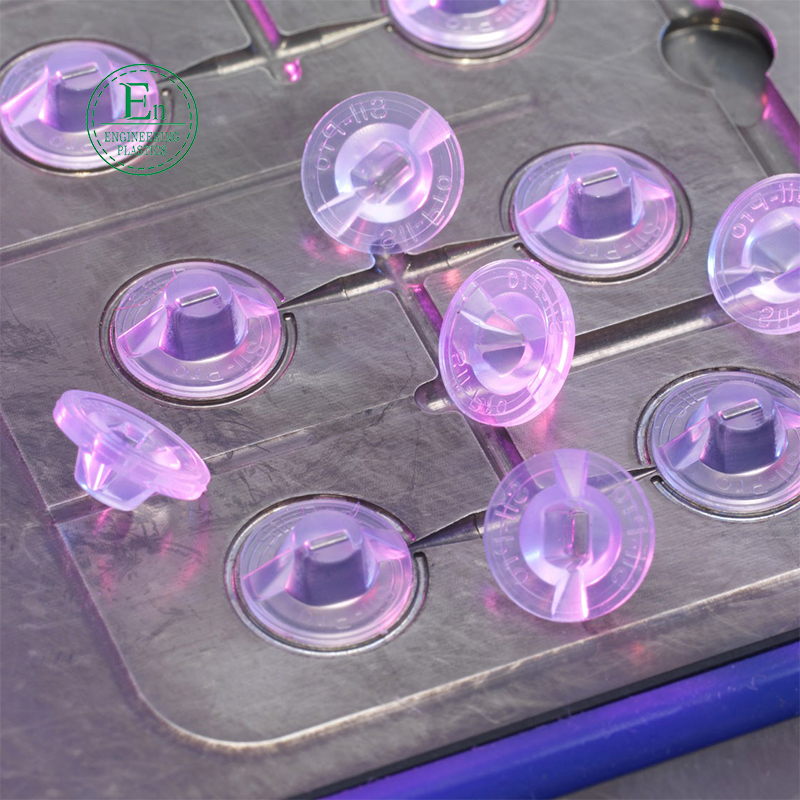

Rubber injection molding

High Precision Mouldings Moulds Making Maker Plastic Injection Mold Plastic Silicone Injection Moulding Part Maker Manufacturer

Product Display

Product Paramenter

|

Company Name

|

Guangdong Engineering plastics Industries(Group)Co,Ltd

|

|||

|

Brand

|

Guangdong Engineering plastics

|

|||

|

Main Product

|

Precision mold, Injection mold, Extrusion mold, Injection plastic products, etc

|

|||

|

Injection Machine

(Double Color)

|

88T, 90T, 120T, 168T, 200T,250T,380T,420T,600T,800T,1000T,1200T,1500T,2200T,2800T,3000T

|

|||

|

Application

|

Electronics industry, Medical industry, Home appliance industry, Aerospace, Shipbuild industry, Household goods, Automobile industry, Machinery industry,Machinery industry,Semicoductor industry,Food processing, Robot industry,etc

|

|||

|

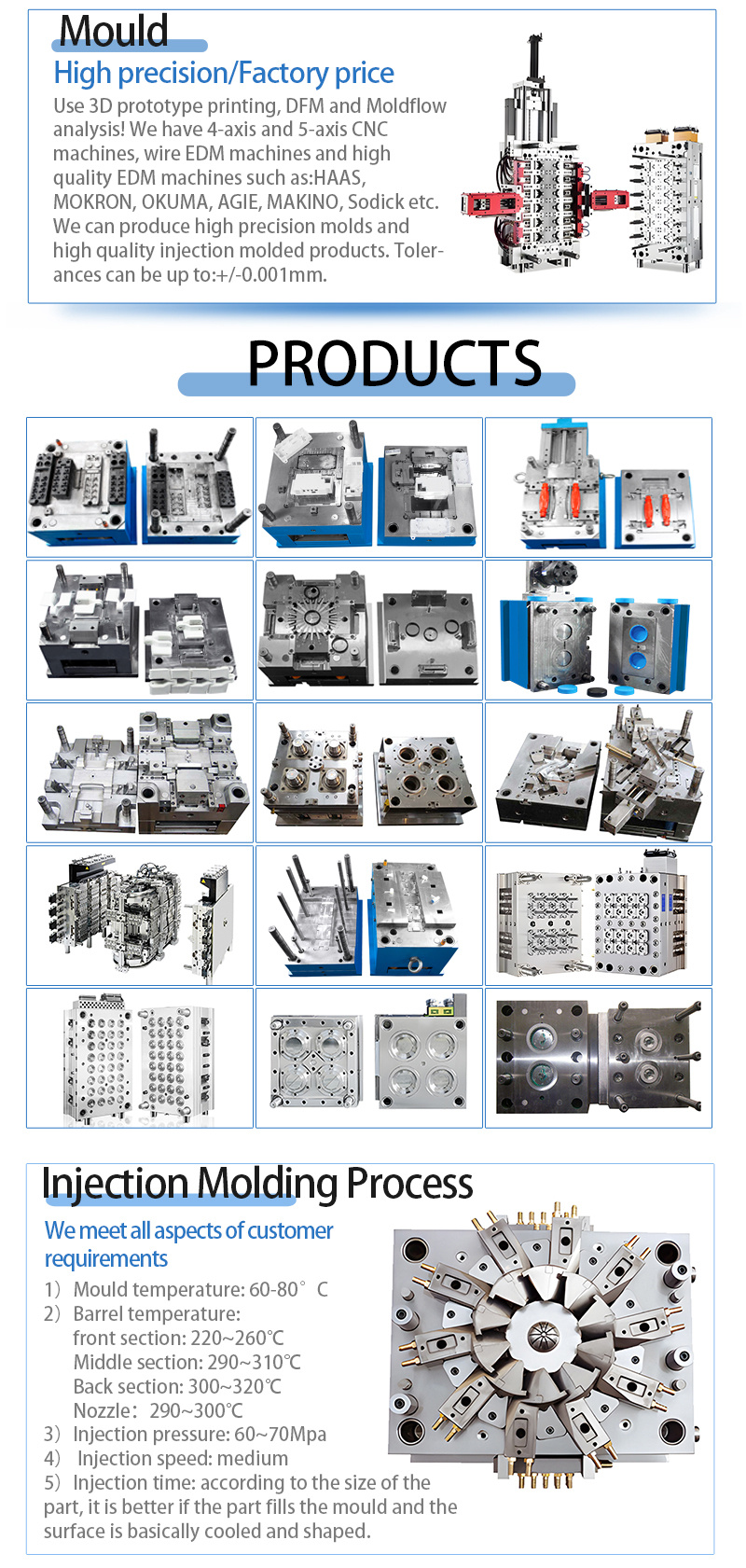

Mould Base

|

LKM Standard,DME Standard,HASCO Standard,FUTABA Standard,Self-made Standad ,etc.

|

|||

|

Mould Material

|

718H/738H/718/738/NAK80/S136/S136H/2738/2316/H13/P20/2344ESR/8407/SKD-61, etc

|

|||

|

Moud Precision

|

+/-0.01mm

|

|||

|

Mould Life

|

100k-1000K shots

|

|||

|

Mould Cavity

|

Single cavity, multi-cavity

|

|||

|

Runner System

|

Hot runner and cold runner

|

|||

|

Manufacturing Equipments

|

Guangdong Engineering plastics company has OWM:Imported CNC equipment, EDM machines, Imported mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines,Double color injection machines,etc

|

|||

|

Plastic Raw Material

|

Nylon6, Nylon66, PA6, PA66, PA6+GF, ABS, ABS+GF, ABS+PC, POM(Derlin), PP, PE, PC, PVC, PMMA(Acrylic),TRU,EPDM,NBR, Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PPS, PEEK, PAI, PI, PBI,etc.

|

|||

|

Color

|

white,black,gray,green,blue,pink,yellow,golden,natural color and custom color,etc

|

|||

|

Surface Treatment Tech

|

Polishing,Painting,Electroplate,Anodizing, Brushing, Silk Screening,Water Transfering, Leather Covering,Texture, Sanblasting,Gilding, UV Painting…

|

|||

|

Product Drawings

|

2D Drawings, 3D Drawings, product samples, or the size of the multi-angle pictures

|

|||

|

Lead time

|

15-30 working days for injection moulds,plastic products according to quantity

|

|||

|

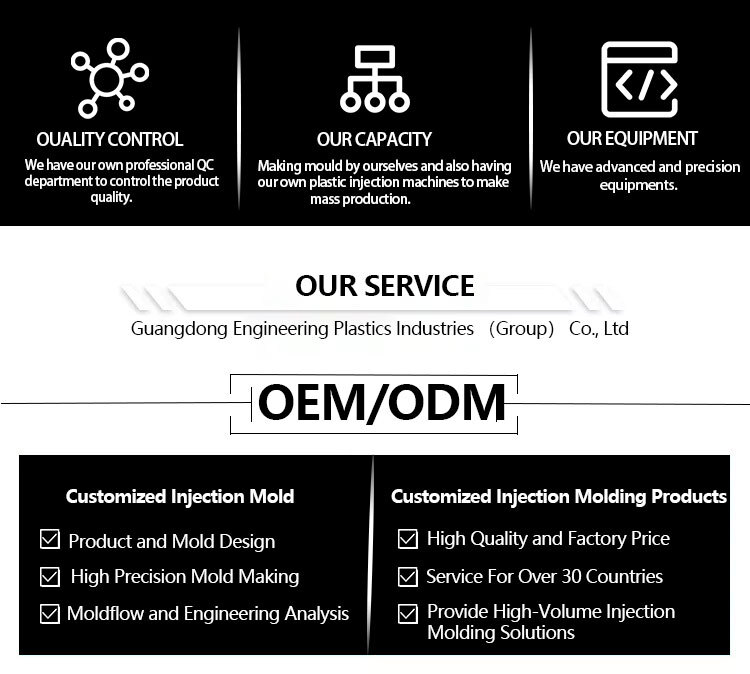

Quanlity System

|

ISO 9001, RoHS Srandard, etc

|

|||

|

Our Spirit

|

"Engineering Plastics" can be used instead of "Steel"!

Science and technology will change the future!

Guangdong Engineering Plastics Industries Company!

|

|||

|

Other

|

24 hours instant and comfortable customer service!

|

|||

|

Shipping status notification during delivery!

|

||||

|

Regular notification of new styles & hot selling styles!

|

||||

About Liquid Silicone

Compared with solid high-temperature vulcanized silicone rubber, liquid silicone rubber is a liquid rubber with good fluidity, fast vulcanization, safety and environmental protection, and can fully meet food-grade requirements. According to the position of the functional group (that is, the cross-linking point) contained in the molecular structure, the liquid rubber with functional groups is often divided into two categories: one is called telechelic liquid rubber with functional groups at both ends of the molecular structure; the other is Active functional groups are randomly distributed in the main chain, that is, those with functional groups in the molecular structure are called non-telechelic liquid rubber.

About silicone rubber

Silicone rubber is an elastic body formed by compounding and vulcanizing with linear polyorganosiloxane as the basic polymer (raw rubber), adding crosslinking agent, reinforcing filler and other compounding agents. According to its commodity form, silicone rubber is divided into two categories: mixing silicone rubber and liquid silicone rubber. Liquid silicone rubber is different from compounded silicone rubber. It is a self-leveling or thixotropic base material (Compound) prepared from linear polyorganosiloxane with a medium degree of polymerization as the base polymer with fillers, various additives and additives. . Generally, large-scale processing equipment is not required for use, and it can be vulcanized into elastomers in the atmosphere or under heating after extrusion, injection molding, and coating according to the variety and application. This book comprehensively and systematically introduces the basic knowledge of liquid silicone rubber. Contents include: basic polymers and compounding agents of condensation-type RTV silicone rubber; condensation-type one-component RTV silicone rubber; addition-type liquid silicone rubber, etc.

use

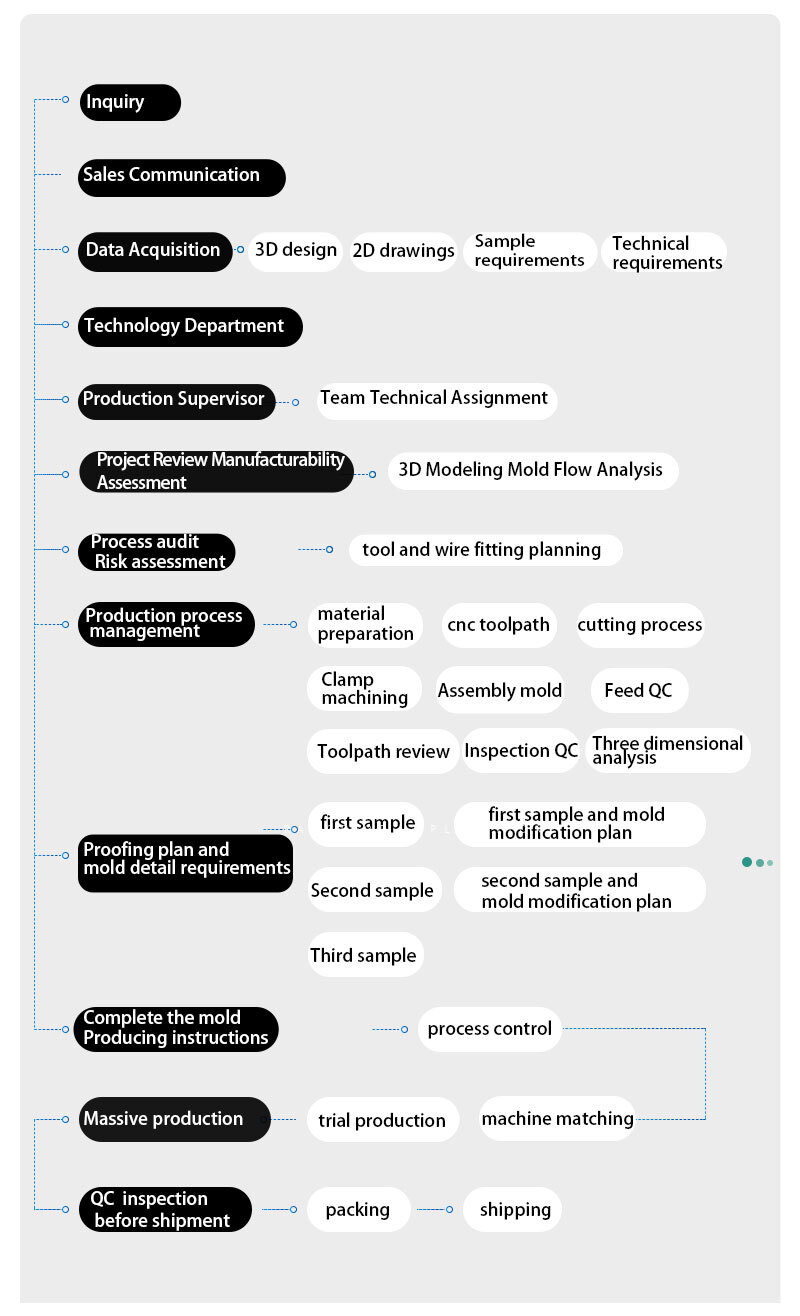

Injection Process

Its product use

Liquid silicone rubber can be used for trademarks, products, pacifiers, medical supplies, coatings, impregnation, etc. It is used for crystal glue, polyurethane, epoxy resin and other molding molds, injection molding process, cake molds and other silicone products. In the electronics industry, it is widely used as moisture-proof, consignment, insulating coating and potting materials for electronic components. , Protect electronic components and assemblies from dust, moisture, shock and insulation. If the electronic components are encapsulated with transparent gel, it can not only play the role of shockproof and waterproof protection, but also can see the components, use the probe to detect the failure of the components and replace them. The damaged silica gel can be repaired by potting again. It can also be used to make product molding molds of materials such as gypsum, wax, epoxy resin, polyester resin, polyurethane resin and low-melting point alloys. Ceramics, toy industry, furniture, home appliances and electronic components industry reproduction, gypsum, cement material molding, wax product molding, model manufacturing, material molding, etc.

Contact customer service, for more product selection

Application

We have a professional engineer team to design custom parts for your needs , we also have ready-made standard moulds that can save your cost and time . We offer ODM/OEM service, Production Design and Mould Design base on your requirement . Providing the sample before mass production , ensure all is OK for you .

If you have any problems or want to get the quoted price of any plastics or machined components, please feel free to contact us. Our engineers will reply to you as soon as possible.

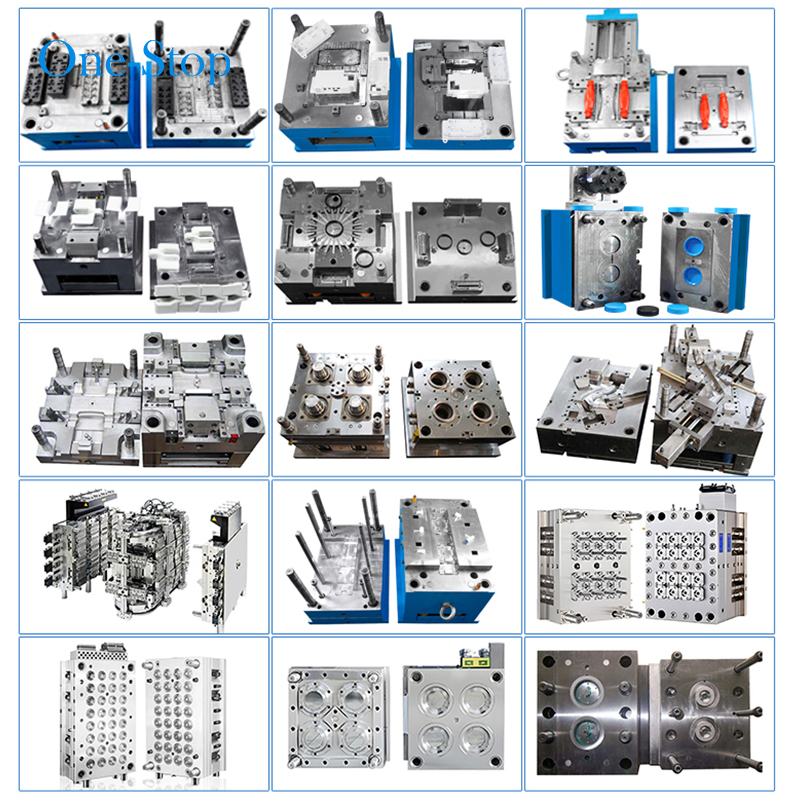

A wide range of injection mold options

Our products cover auto parts mold, electrical appliances injection mold, medical machinery and so on. We provide products and services to more than 60 countries and regions in the world, including Europe, the United States and Southeast Asia.

Our Factory

(Our factory has 100 sets of precision processing equipment, welcome to visit our factory!)

Reliable mold expert 15+ years' experience, Cooperated with many world famous brands for many years, Specialize in large and complex injection mold making, One-stop service from design to production.

Certificate

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

Cooperation